Contents

What is the bullwhip effect?

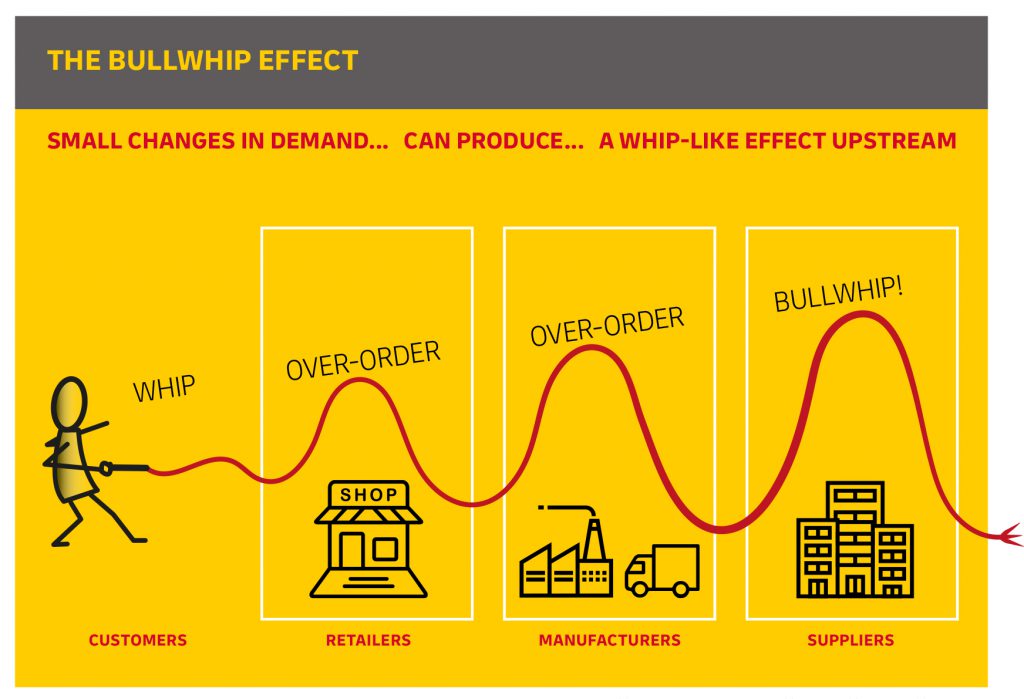

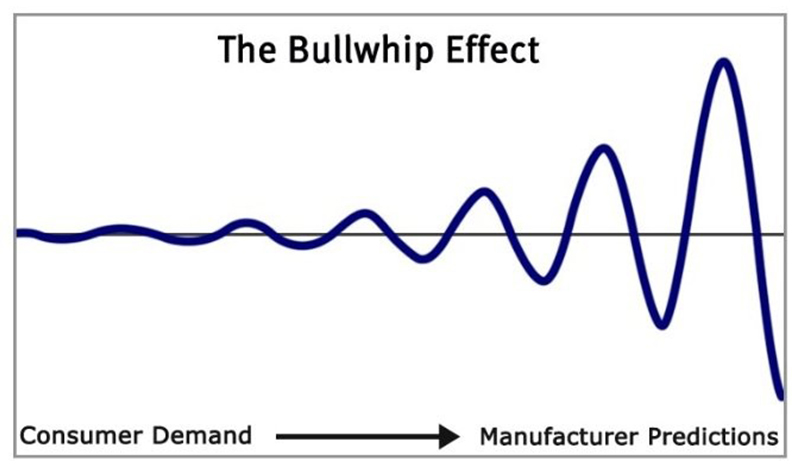

The bullwhip effect is a distribution channel phenomenon in which demand forecasts yield supply chain inefficiencies. It refers to increasing swings in inventory in response to shifts in consumer demand as one moves further up the supply chain.

A simplified example of the bullwhip effect:

The bullwhip effect often occurs when retailers become highly reactive to demand, and in turn, amplify expectations around it, which causes a domino effect along the supply chain. Suppose, for example, a retailer typically keeps 100 six-packs of one soda brand in stock. If it normally sells 20 six-packs a day, it would order that replacement amount from the distributor. But one day, the retailer sells 70 six-packs and assumes customers will start buying more product, and responds by ordering 100 six-packs to meet this higher forecasted demand.

The distributor may then respond by ordering double, or 200 six-packs, from the manufacturer to ensure they do not run out. The manufacturer then produces 250 six-packs to be on the safe side. In the end, the increased demand has been amplified up the supply chain from to 100 six-packs at the customer level to 250 at the manufacturer.

This example is highly simplified but conveys the sense of exponentially increasing misalignment as actions and reactions continue up and down the chain. The bullwhip effect also occurs as a result of lowered demand at the customer level (which causes shortages when inaccurate) and can be caused at other places along the chain.

Causes of the bullwhip effect:

Companies must forecast customer demand based on insufficient information, and try to predict how much product customers will actually want while accounting for the complex factors that enable that amount to be delivered correctly and on time. At every stage of the supply chain there are possible fluctuations and disruptions, which in turn influence the myriad supplier orders. Changes in customer demand directly influence all the other factors along the chain, including inventory. However, the bullwhip effect can occur even in relatively stable markets where the demand is essentially constant.

Forecasting demand has always been a difficult endeavor, and the increasing complexity of today’s global supply chains intensifies that difficulty, as does increasing consumer preference for omnichannel and e-commerce. A few of the most common dependencies that can cause a bullwhip effect are:

- Lead-time issues such as manufacturing delays

- Less-than-optimal decisions made by supply chain stakeholders at any point along the chain, for example, customer service or shipping

- A lack of communication and alignment between each link or stakeholder organization in the supply chain

- Over- or under-reacting to demand expectations, such as ordering too many units or not enough

- Customer companies, often retailers, waiting until orders build up before placing orders with their suppliers, a practice called order batching

- Discounts, cost changes and other price variations that disrupt regular buying patterns

- Inaccurate forecasts from over-reliance on historical demand to predict future demand

Consequences of bullwhip effect:

In addition to greater safety stocks, the described effect can lead to either inefficient production or excessive inventory, as each producer needs to fulfill the demand of its customers in the supply chain. This also leads to a low utilization of the distribution channel.

In spite of having safety stocks there is still the hazard of stock-outs which result in poor customer service and lost sales. In addition to the (financially) hard measurable consequences of poor customer services and the damage to public image and loyalty, an organization has to cope with the ramifications of failed fulfillment which may include contractual penalties. Moreover, repeated hiring and dismissal of employees to manage the demand variability induces further costs due to training and possible lay-offs.

The impact of the bullwhip effect has been especially acute at the beginning stages of the COVID-19 pandemic, when sudden spikes in demand for everything from medical supplies such as masks or ventilators to consumer items such as toilet paper or eggs created feedback loops of panic buying, hoarding, and rationing.

News about logistics in Vietnam:

How will Vietnam’s logistics industry develop in the future?

Logistic challenges and the impact of a pandemic